Bayanin Kamfanin

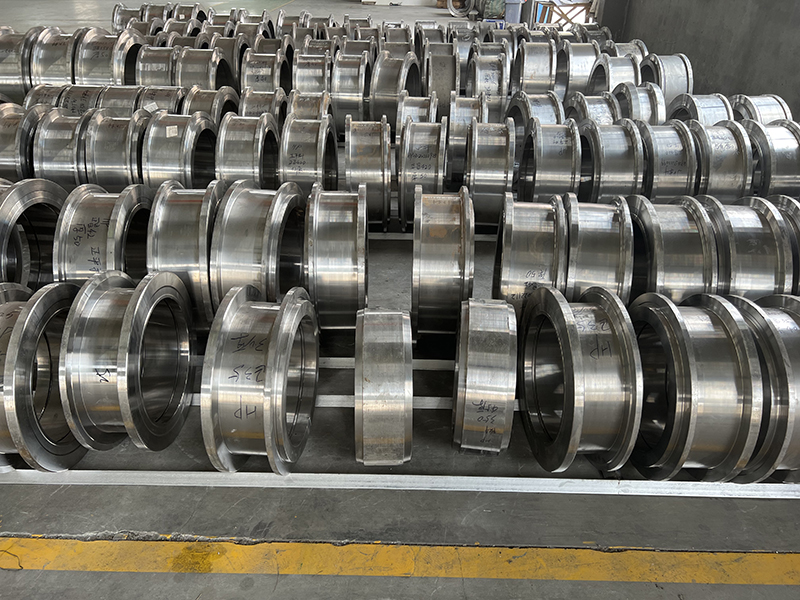

Hangzhou Hanpai Mold Technology Co. Ltd. An Kafa a 2012, shi ne Majalisar Memba na Zhejiang Die & Mould Industry Association.We ƙware a R&D da kuma samar da pellet niƙa sassa, kamar ciyar pellets zobe mutu, biomass pellets zobe mutu, Organic taki pellets. zobe mutu, cat zuriyar dabbobi pellets zobe mutu, abin nadi harsashi da sauransu.Bayar da lahani na pellet mutu ga duniya shine burinmu na ci gaba.

A cikin 2017 shekara an karrama mu a matsayin babban kamfani na Hangzhou kuma mun sami amincewar masana'antun kimiyya da fasaha na lardin Zhejiang.A cikin 2018, an canza sunan kamfaninmu daga Hangzhou Hanpai Mold Co., LTD zuwa Hangzhou Hanpai Mold Technology Co., LTD.Mu ne Mai Bayar da Audited ta SGS, yanzu mun sami takardar shaidar tsarin kula da ingancin ISO 9001.

Happy Mold amfani high quality X46Cr13 bakin karfe, CNC zurfin rami hakowa inji, injin quenching makera, sauran ci-gaba kayan aiki da kuma musamman tsari;A lokaci guda muna da ƙungiyar manyan masu fasaha da kuma tsarin kula da tsarin samar da inganci, wanda ke haifar da Happy Mold kyakkyawan inganci da kyakkyawan suna. -40%

Farin Ciki

"HAPPY MOULD" shine alamar kasuwancin mu, ta amfani da Happy Mold na iya sa abokin ciniki ya ceci mai yawa farashin samarwa, ƙara riba da gasa kasuwa saboda samar da santsi, ingancin pellets mai kyau, ingantaccen samarwa, ƙarancin wutar lantarki, da sauƙin aiki. zai iya rage ma'aikata ƙarfin aiki, wanda ke kawo farin ciki ga kowa da kowa.

Hanpai Mold ya lashe fadi da yabo daga abokan ciniki a gida da waje, kuma muna sa ido don samar da kyau kwarai da sifili lahani mold ga duniya pellet samar Enterprises.

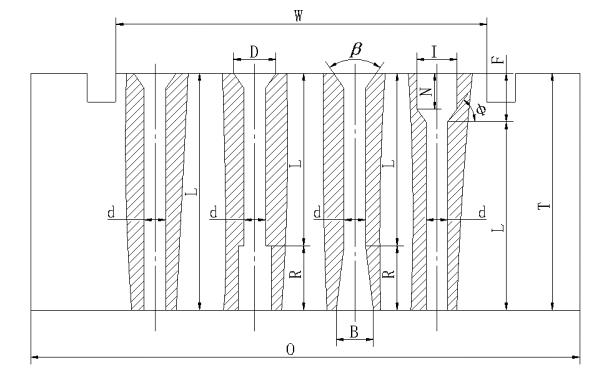

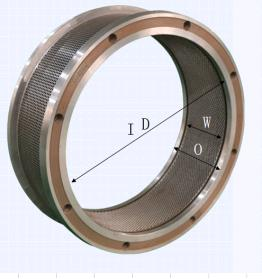

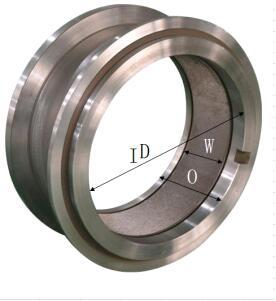

ID a cikin adadi - diamita na ciki na mutuwar zobe;

O -- jimlar nisa na zobe mutu;

W -- tasiri nisa na zobe mutu (aiki nisa);

d -- buɗewar mutuwar zobe (girman ramin pellet ɗin da aka matse);

L - tasiri tsawon ramin mutu;

T -- jimlar kauri na zobe mutu;

D -- diamita na mashigai na ramin mutu;

β -- mutu rami conical mashigan mashiga;

Siffar ramin injin niƙa ya mutu: siffofin ramin da aka saba amfani da su sun haɗa da madaidaicin rami, rami mai juyi, rami mai mazugi na waje da ramin matakin canji na gaba tare da mazugi.Yin aikin rami madaidaiciya yana da sauƙi, mafi yawan amfani;Tsawon tsayi mai tasiri na ramin mutuwa da lokacin extrusion kayan aiki a cikin ramin mutuwa yana raguwa ta hanyar rami na baya da rami na waje, ya dace da sarrafa pellets tare da diamita ƙasa da φ10mm.Kyakkyawan ramin mataki mai kyau tare da siffar conical ya dace da sarrafa abincin pellet wanda diamita ya wuce φ10mm tare da babban abun ciki na fiber danyen.Baya ga nau'ikan nau'ikan ramuka guda 4 da ke sama, akwai nau'ikan nau'ikan ramuka, kamar ramin conical na waje, ramin mazugi na ciki da ramin da ba na madauwari ba, amma ba a saba amfani da shi ba.

R -- zurfin juyi reaming (ramin taimako na matsa lamba);

B - diamita na juyawa reaming (ramin taimako na matsa lamba);

φ -- Madaidaicin kusurwar canjin yanayi;

F -- zurfin reaming tabbatacce;

I -- tabbataccen diamita;

L/d -- tsayin-bude rabo (raɗin matsawa).

Kauri na pellet niƙa mutu (T): Kauri na zobe mutu kai tsaye rinjayar ƙarfi, taurin mutuwar zobe da kuma yadda ya dace, ingancin pelleting.A cikin duniya, ana zabar kauri (T) na zobe na mutun daga 32 ~ 127mm (mafi ƙarancin kauri a China ya kasance 13mm).

Ingantacciyar tsayin pellet niƙa mutu rami (L): Ingantacciyar tsayin zobe mutu rami yana nufin tsayin ramin mutu don extrusion abu (forming).Tsawon tsayin tasiri na ramin mutuwa, tsawon lokacin extrusion na abu a cikin rami mai mutu, da wuyar pellets an yi, sa'an nan kuma ƙarfi da ingancin pellets sun fi kyau.Akasin haka, ƙwanƙwasa suna kwance, ƙwanƙwasa yana da girma, kuma ingancin pellet ya ragu.

Diamita mai maƙalli (D) na ramin mutuwa: diamita na ramin abinci ya kamata ya fi girma diamita na ramin mutuwa (d), don rage juriya na kayan cikin rami, don sauƙaƙe shigar su. cikin ramin mutuwa.Akwai nau'i nau'i na asali guda uku na ramukan abinci, wato madaidaicin rami, rami mai mazugi da rami mai lankwasa.Don albarkatun kasa tare da babban abun ciki na fiber, saboda bambancin halaye na granulation, ana buƙatar rage juriya ta hanyar ramin mutu a cikin aiwatar da aikin. granulation.Don haka, ya kamata a tsara ramin mutuwa zuwa sassa biyu, sashen ciyar da extrusion L da sashin fitarwa na ragewa R, wato L+R=T.Akwai nau'i nau'i na asali guda uku na ramin zubar da ruwa: madaidaiciya rami, rami mai mazugi da haɗin ramin mazugi da rami madaidaiciya, daga cikinsu madaidaicin rami da ramin mazugi an fi amfani da su, matsakaicin buɗaɗɗensa ya ɗan fi diamita diamita d. , Zurfinsa ya dogara da daidaitaccen tsayin aiki mai tasiri L. A wasu lokuta, musamman ma lokacin da kayan aiki ya bayyana a cikin rami mai zurfi zai fadada kuma ya toshe, ya dace don amfani da haɗin kai na mazugi rami da madaidaiciya rami , ko amfani. na mazugi rami.