Tuam txhab Profile

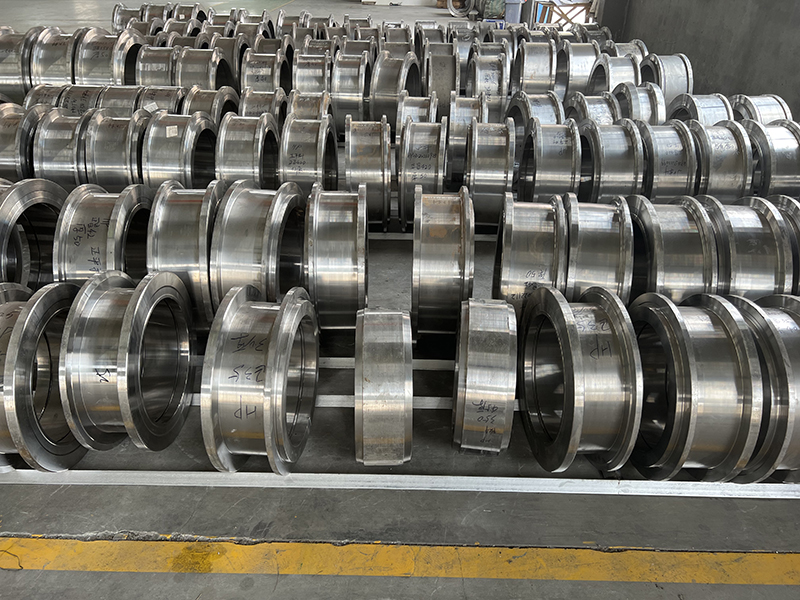

Hangzhou Hanpai Mould Technology Co. Ltd. yog Founded hauv 2012, nws yog Council Member ntawm Zhejiang Die & Pwm Industry Association.Peb tshwj xeeb hauv R & D thiab tsim cov pellet zeb tshuab qhov chaw, xws li pub pellets nplhaib tuag, biomass pellets nplhaib tuag, organic chiv pellets nplhaib tuag, miv litter pellets nplhaib tuag, cov menyuam plhaub thiab lwm yam.Muab zero defect pellet zeb tuag rau lub ntiaj teb no yog peb txoj kev loj hlob lub hom phiaj.

Nyob rau hauv 2017 xyoo peb tau qhuas raws li Hangzhou high-tech enterprise thiab dhau qhov kev pom zoo ntawm Zhejiang xeev kev tshawb fawb thiab thev naus laus zis kev lag luam.Nyob rau hauv 2018, lub npe ntawm peb lub tuam txhab tau hloov los ntawm Hangzhou Hanpai Mould Co., LTD rau Hangzhou Hanpai Mould Technology Co., LTD.Peb yog cov Audited Supplier los ntawm SGS, tam sim no peb tau txais ISO 9001 zoo tswj system daim ntawv pov thawj.

Zoo siab Pwm siv zoo X46Cr13 stainless hlau, CNC sib sib zog nqus qhov drilling tshuab, nqus quenching rauv, lwm yam khoom siv siab heev thiab cov txheej txheem tshwj xeeb;Nyob rau tib lub sij hawm peb muaj ib pab pawg neeg ntawm high-level kws txawj thiab nruj ntau lawm zoo tswj system, uas tsim lub Happy Mould zoo heev thiab zoo neeg lub koob npe nrov.Zoo Pwm yuav ua kom efficiency ntawm ntau lawm nce 10-40%, tus nqi ntawm ntau lawm txo 10 -40%

Pwm zoo siab

"Zoo siab MOULD" yog peb lub cim lag luam, siv Cov Pwm Zoo siab tuaj yeem ua rau cov neeg siv khoom txuag tau ntau tus nqi tsim khoom, nce cov txiaj ntsig thiab kev lag luam kev sib tw vim nws cov khoom lag luam du, zoo pellets zoo, kev ua haujlwm siab, kev siv hluav taws xob tsawg, thiab kev ua haujlwm yooj yim. tuaj yeem txo cov neeg ua haujlwm siv zog ua haujlwm, uas ua rau muaj kev zoo siab rau txhua tus.

Hanpai Mould tau txais kev qhuas dav los ntawm cov neeg siv khoom hauv tsev thiab txawv teb chaws, thiab peb tab tom nrhiav rau pem hauv ntej los muab cov pwm zoo thiab tsis zoo rau cov lag luam thoob ntiaj teb.

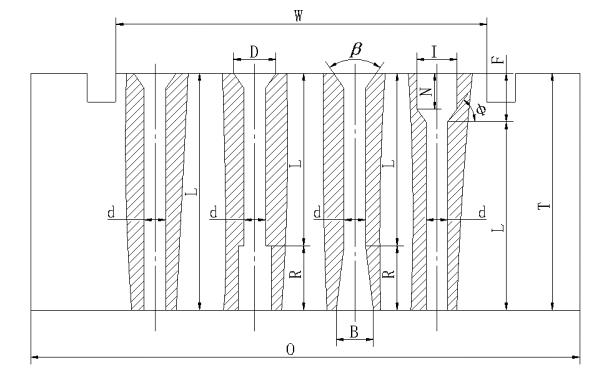

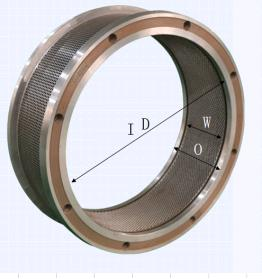

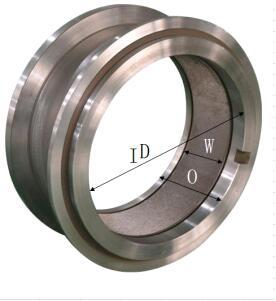

ID hauv daim duab - puab txoj kab uas hla ntawm lub nplhaib tuag;

O - tag nrho qhov dav ntawm lub nplhaib tuag;

W - qhov dav dav ntawm lub nplhaib tuag (ua haujlwm dav dav);

d - aperture ntawm lub nplhaib tuag (qhov loj ntawm nias pellet);

L - qhov ntev ntawm qhov tuag;

T - tag nrho thickness ntawm lub nplhaib tuag;

D - taper inlet txoj kab uas hla ntawm lub qhov tuag;

β - tuag qhov conical inlet Lub kaum sab xis;

Lub qhov zoo ntawm lub pellet zeb tuag: qhov feem ntau siv lub qhov duab feem ntau muaj xws li lub qhov ncaj, thim rov qab lub qhov, txheej lub khob hliav qab reaming qhov thiab rau pem hauv ntej hloov kauj ruam qhov nrog lub khob hliav qab.Ncaj qhov ua yog yooj yim, feem ntau siv;Qhov ntev ntawm qhov tuag qhov tuag thiab cov khoom siv extrusion lub sij hawm nyob rau hauv lub qhov tuag yog txo los ntawm lub thim rov qab lub qhov thiab lub puab taper qhov, nws yog tsim rau kev ua cov pellets nrog txoj kab uas hla tsawg tshaj φ10mm.Qhov zoo reaming kauj ruam qhov nrog conical zoo yog tsim rau kev ua pellet pub uas lub cheeb ntau tshaj φ10mm nrog siab crude fiber ntau.Ntxiv rau qhov saum toj no 4 hom ntawm lub qhov duab, muaj ntau yam ntawm lub qhov, xws li lub qhov conical txheej, puab lub khob hliav qab lub qhov thiab lub qhov uas tsis yog-cim, tab sis kev siv tsis yog ntau.

R - qhov tob ntawm qhov rov qab reaming (siab nyem qhov);

B - txoj kab uas hla ntawm rov qab reaming (lub siab nyem qhov);

φ - zoo reaming hloov lub kaum sab xis;

F - zoo reaming qhov tob;

Kuv - zoo reaming txoj kab uas hla;

L / d - qhov ntev-aperture ratio (compression ratio).

Thickness ntawm pellet zeb tuag (T): Lub thickness ntawm lub nplhaib tuag ncaj qha cuam tshuam lub zog, hardness ntawm lub nplhaib tuag thiab cov efficiency, zoo ntawm pelleting.Nyob rau hauv lub ntiaj teb no, lub thickness (T) ntawm lub nplhaib tuag feem ntau yog xaiv los ntawm 32 ~ 127 hli (qhov tsawg kawg nkaus thickness nyob rau hauv Tuam Tshoj tau 13 hli).

Siv tau ntev ntawm pellet zeb tuag qhov (L): Qhov ntev ntawm lub nplhaib tuag qhov yog hais txog qhov ntev ntawm qhov tuag qhov rau cov khoom extrusion (sib sau).Qhov ntev ntev ntawm qhov tuag qhov tuag, lub sij hawm extrusion ntev ntawm cov khoom nyob rau hauv lub qhov tuag, lub pellets nyuaj dua, ces lub zog thiab cov pellets zoo dua.Ntawm qhov tsis sib xws, cov pellets yog xoob, pulverization tus nqi siab, thiab cov pellet zoo yog txo.

Tapered inlet txoj kab uas hla (D) ntawm lub qhov tuag: txoj kab uas hla ntawm lub qhov pub yuav tsum loj tshaj qhov txoj kab uas hla ntawm lub qhov tuag (d), thiaj li yuav txo tau cov tsis kam ntawm cov khoom rau hauv lub qhov, thiaj li mus pab txhawb lawv nkag. rau hauv qhov tuag.Muaj peb hom kev pub noj, uas yog lub qhov ncaj, lub khob hliav qab thiab lub qhov nkhaus.Rau cov ntaub ntawv raw nrog cov ntsiab lus fiber ntau, vim qhov sib txawv ntawm cov yam ntxwv granulation, nws yuav tsum tau txo qhov tsis kam ntawm qhov tuag qhov hauv cov txheej txheem granulation.Vim li no, lub qhov tuag yuav tsum tau tsim rau hauv ob ntu, pub extrusion seem L thiab decompression paug seem R, uas yog L + R = T.Muaj peb hom kev yooj yim ntawm decompression paug qhov: qhov ncaj, lub khob hliav qab thiab ua ke ntawm lub khob hliav qab thiab lub qhov ncaj, cov uas lub qhov ncaj thiab lub khob hliav qab yog feem ntau siv, nws qhov siab tshaj plaws aperture yog me ntsis loj dua qhov tuag qhov taub d , nws qhov tob yog nyob ntawm qhov sib txuas ua haujlwm ntev L. Qee qhov xwm txheej, tshwj xeeb tshaj yog thaum cov khoom ua haujlwm tshwm sim hauv qhov tob ntawm qhov siab yuav nthuav dav thiab ntsaws, nws tsim nyog siv qhov kev hloov pauv ntawm lub khob hliav qab thiab lub qhov ncaj, lossis siv ntawm lub khob hliav qab.