Mbiri Yakampani

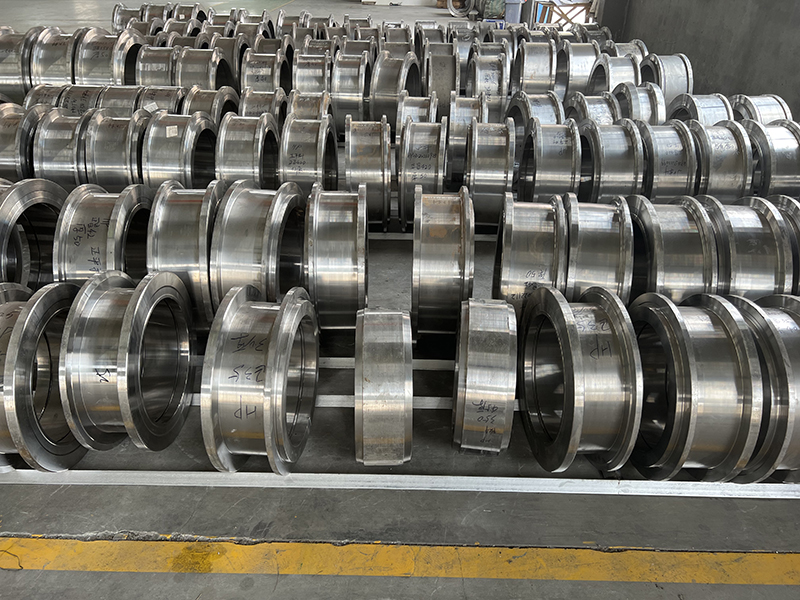

Hangzhou Hanpai Mold Technology Co. Ltd. inakhazikitsidwa mu 2012, ndi Council Member wa Zhejiang Die & Mould Industry Association.We amakhazikika mu R&D ndi kupanga mbali pellet makina mphero, monga chakudya pellets mphete kufa, biomass pellets mphete kufa, organic feteleza pellets. mphete kufa, mphaka zinyalala pellets mphete kufa, wodzigudubuza chipolopolo ndi zina zotero.Perekani zero defect pellet mill die for the world ndiye cholinga chathu chachitukuko.

M'chaka cha 2017 tidalemekezedwa ngati bizinesi yapamwamba ya Hangzhou ndipo tidavomereza mabizinesi asayansi ndiukadaulo m'chigawo cha Zhejiang.Mu 2018, dzina la kampani yathu linasinthidwa kuchoka ku Hangzhou Hanpai Mold Co., LTD kukhala Hangzhou Hanpai Mold Technology Co., LTD.We are Audited Supplier ndi SGS, tsopano talandira satifiketi ya ISO 9001 Quality Management System.

Happy Mold amagwiritsa ntchito chitsulo chosapanga dzimbiri cha X46Cr13, makina obowola mabowo akuya a CNC, ng'anjo yozimitsa, zida zina zapamwamba komanso njira yapadera;Pa nthawi yomweyo tili ndi gulu la amisiri apamwamba ndi okhwima dongosolo kupanga khalidwe kulamulira khalidwe, amene kulenga Happy Mold khalidwe labwino kwambiri ndi wabwino kasitomala reputation.Happy Mould akhoza kupanga dzuwa la kupanga Kuchulukitsa 10-40%, mtengo wa kupanga kuchepa 10 -40%

Wodala Mold

"HAPPY MOULD" ndi chizindikiro chathu, kugwiritsa ntchito Happy Mold kungapangitse kasitomala kusunga ndalama zambiri zopangira, kuonjezera phindu ndi mpikisano wamsika chifukwa cha kupanga kwake kosalala, khalidwe labwino la pellets, kupanga bwino kwambiri, kugwiritsa ntchito mphamvu zochepa, komanso ntchito yosavuta. zitha kuchepetsa kulimbikira kwa ogwira ntchito, zomwe zimabweretsa chisangalalo kwa aliyense.

Hanpai Mold yapindula kwambiri ndi makasitomala akunyumba ndi kunja, ndipo tikuyembekezera kupereka nkhungu zabwino kwambiri komanso ziro zamabizinesi opanga ma pellet padziko lonse lapansi.

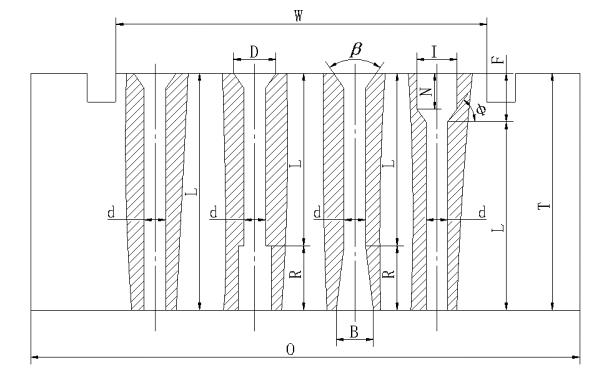

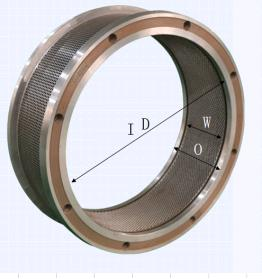

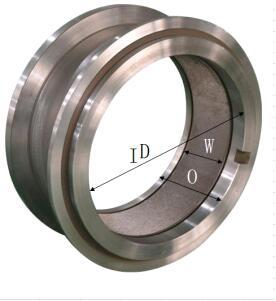

ID pachithunzi - mkati mwake mwa mphete;

O -- m'lifupi mwake lonse la mphete;

W - m'lifupi mwake mwa mphete (yogwira ntchito m'lifupi);

d --bowo la mphete kufa (dzenje kukula kwa pellet woponderezedwa);

L - kutalika kwa dzenje lakufa;

T - makulidwe onse a mphete amafa;

D - m'mimba mwake wa dzenje lakufa;

β --bowo lolowera m'mphepete;

Maonekedwe a dzenje la mphero ya pellet amafa: mawonekedwe omwe amagwiritsidwa ntchito nthawi zambiri amaphatikizira dzenje lolunjika, dzenje lobwerera kumbuyo, dzenje lakunja la cone reaming ndi dzenje lolowera kutsogolo ndi chulu.Kukonza dzenje lolunjika ndikosavuta, kugwiritsidwa ntchito kofala kwambiri;Kutalika kothandiza kwa dzenje lakufa ndi nthawi yotulutsa zinthu mu dzenje lakufa kumachepetsedwa ndi dzenje lakumbuyo ndi dzenje lakunja la taper, ndiloyenera kukonza ma pellets okhala ndi mainchesi osakwana φ10mm.Bowo labwino la reming lomwe lili ndi mawonekedwe owoneka bwino ndiloyenera kukonza chakudya chamtundu wa pellet chomwe m'mimba mwake chimaposa φ10mm chokhala ndi ulusi wambiri wamafuta.Kuphatikiza pa mitundu 4 yomwe ili pamwambapa, pali mawonekedwe osiyanasiyana a dzenje, monga dzenje lakunja, dzenje lamkati ndi dzenje losazungulira, koma kugwiritsa ntchito sikofala.

R - kuya kwa reverse reming (bowo lothandizira kupanikizika);

B - awiri a reverse reming (bowo lothandizira kupanikizika);

φ -- njira yabwino yosinthira njira;

F - kuzama kwabwino;

Ine -- wiritsani bwino;

L/d -- kutalika-kabowo chiŵerengero (kuponderezana chiŵerengero).

Makulidwe a pellet mphero kufa (T): makulidwe a mphete kufa mwachindunji zimakhudza mphamvu, kuuma kwa mphete kufa ndi dzuwa, khalidwe la pelleting.Padziko lapansi, makulidwe (T) a mphete ya mphete nthawi zambiri amasankhidwa kuchokera ku 32 ~ 127mm (kutsika kochepa ku China kwakhala 13mm).

Utali wokwanira wa pellet mphero die hole (L) : Utali wothandiza wa mphete yofera dzenje imatanthawuza kutalika kwa dzenje la kufa kwa zinthu zotulutsa (kupanga).Kutalika kwabwino kwa dzenje lakufa, nthawi yowonjezereka ya zinthu zomwe zili mu dzenje lakufa, zimakhala zovuta kupanga ma pellets, ndiye mphamvu ndi ma pellets zimakhala bwino.M'malo mwake, ma pellets ndi otayirira, kuchuluka kwa pulverization ndikwambiri, ndipo mtundu wa pellet umachepetsedwa.

Tapered inlet diameter (D) ya dzenje lakufa: kutalika kwa dzenje la chakudya kuyenera kukhala kokulirapo kuposa kukula kwa dzenje (d), kuti muchepetse kukana kwazinthuzo mu dzenje, kuti athe kulowa nawo. m'dzenje lakufa.Pali mitundu itatu yofunikira ya mabowo a chakudya, omwe ndi dzenje lowongoka, dzenje la cone ndi dzenje lopindika.Pazinthu zopangira zokhala ndi ulusi wambiri, chifukwa cha kusiyana kwa mawonekedwe a granulation, zimafunika kuchepetsa kukana kudzera mu dzenje lakufa panthawiyi. granulation.Pachifukwa ichi, dzenje lakufa liyenera kupangidwa kukhala magawo awiri, gawo la feed extrusion L ndi gawo la discompression discharge R, lomwe ndi L+R=T.Pali mitundu itatu yofunikira ya dzenje lotulutsa decompression: dzenje lowongoka, dzenje la cone ndi kuphatikiza dzenje la cone ndi dzenje lowongoka, pomwe dzenje lowongoka ndi dzenje ndizomwe zimagwiritsidwa ntchito kwambiri, kabowo kake kokulirapo ndi kokulirapo pang'ono kuposa dzenje lakufa d. , kuya kwake kumadalira lolingana ogwira ntchito kutalika L. Nthawi zina, makamaka pamene zinthu processing zikuoneka mu dzenje lakuya mavuto adzakulitsa ndi pulagi, ndi koyenera kugwiritsa ntchito kusintha kaphatikizidwe ka chulucho dzenje ndi dzenje molunjika , kapena ntchito wa dzenje la cone.