Profile yekambani

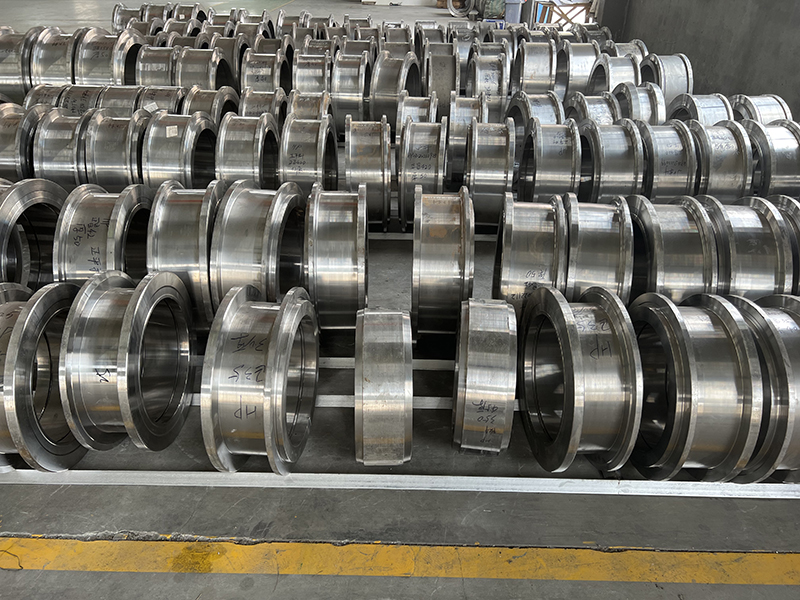

Hangzhou Hanpai Mold Technology Co. Ltd. yakavambwa muna 2012, inhengo yeKanzuru yeZhejiang Die & Mould Industry Association. Isu tinoshanda muR&D nekugadzirwa kwezvikamu zvemuchina wechigayo, senge feed pellets ring kufa, biomass pellets mhete dzinofa, organic fetereza pellets. mhete kufa, katsi litter pellets mhete inofa, roller shell uye zvichingodaro.Ipa zero defect pellet mill die for the world ndicho chinangwa chedu chebudiriro.

Mugore ra2017 takaremekedzwa seHangzhou high-tech bhizinesi uye takapasa mvumo yedunhu reZhejiang mabhizinesi esainzi uye tekinoroji.Muna 2018, zita rekambani yedu rakachinjwa kubva kuHangzhou Hanpai Mold Co., LTD kuita Hangzhou Hanpai Mold Technology Co., LTD.Isu tiri Audited Supplier neSGS, ikozvino tawana ISO 9001 quality management system certificate.

Inofara Mold shandisa yemhando yepamusoro X46Cr13 simbi isina tsvina, CNC yakadzika gomba yekuchera muchina, vacuum yekudzima choto, mimwe michina yepamberi uye yakasarudzika maitiro;Panguva imwecheteyo isu tine boka revanyanzvi vepamusoro-soro uye yakasimba yekugadzirwa kwemhando yekudzora system, iyo inogadzira iyo Happy Mold yakanakisa mhando uye yakanaka mutengi reputation.Happy Mold inogona kuita kugona kwekugadzira Kuwedzera 10-40%, mutengo wekugadzira unoderera gumi -40%

Happy Mold

"HAPPY MOULD" chiratidzo chedu chekutengesa, kushandisa Happy Mold kunogona kuita kuti mutengi achengetedze mari yakawanda yekugadzira, kuwedzera purofiti uye kukwikwidza kwemusika nekuda kwekugadzirwa kwayo kwakanaka, kunaka kwepellets, kugona kwekugadzira kwakanyanya, kushandiswa kwesimba shoma, uye kushanda kuri nyore. zvinogona kuderedza kushanda nesimba kwevashandi, izvo zvinounza mufaro kumunhu wese.

Hanpai Mold yakunda kurumbidzwa kwakakura kubva kune vatengi kumba nekune dzimwe nyika, uye isu tiri kutarisira kupa yakanakisa uye zero defect mold kumabhizinesi epasi rose ekugadzira pellet.

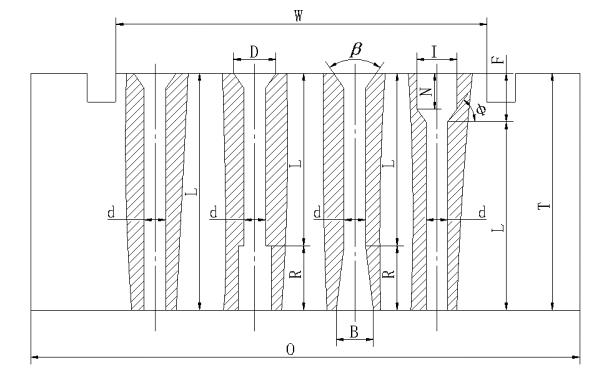

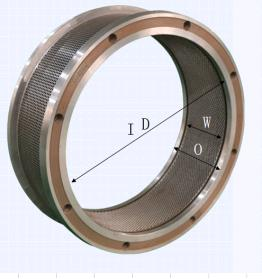

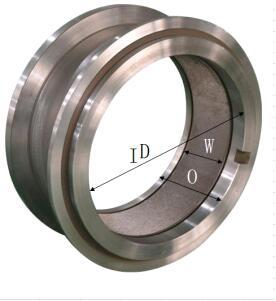

ID mumufananidzo -- yemukati dhayamita yemhete kufa;

O -- hupamhi hwemhete inofa;

W -- hupamhi hunobudirira hwemhete kufa (kushanda pamusoro pehupamhi);

d -- aperture yemhete kufa (gomba saizi yekutsikirirwa pellet);

L -- hurefu hunobudirira hwegomba rinofa;

T -- kuwanda kwemhete kunofa;

D - taper inlet dhayamita yegomba rinofa;

β -- die gole conical inlet Angle;

Iyo gomba chimiro chechigayo chinofa: maumbirwo egomba anowanzo shandiswa anonyanya kusanganisira gomba rakatwasuka, reverse nhanho gomba, rekunze koni reaming gomba uye mberi shanduko nhanho ine cone.Yakarurama gomba kugadzirisa iri nyore, inonyanya kushandiswa;Hurefu hunobudirira hwegomba rekufa uye nguva yekuwedzeredza zvinhu mugomba rekufa inoderedzwa nereverse nhanho gomba uye yekunze taper gomba, inokodzera kugadzirisa mapellets ane dhayamita isingasviki φ10mm.Gomba rakanaka rekusimudzira nhanho ine conical chimiro chakakodzera kugadzirisa pellet feed iyo dhayamita inodarika φ10mm ine yakakwira crude fiber content.Pamusoro pemhando ina dziri pamusoro pemaumbirwo egomba, kune akasiyana maumbirwo egomba, senge rekunze conical gomba, yemukati cone gomba uye isina-yakatenderera gomba, asi kushandiswa hakuna kujairika.

R -- kudzika kwe reverse reming (gomba rekudzikinura);

B -- dhayamita rekudzokera kumashure (kumanikidza gomba);

φ -- yakanaka reming transition Engle;

F -- positive reming deep;

I -- positive reaming dhayamita;

L/d -- kureba-aperture ratio (compression ratio).

Ukobvu hwepellet mill die (T): Ukobvu hwemhete inofa inobata zvakananga kusimba, kuoma kwemhete kufa uye kushanda zvakanaka, mhando yepelleting.Munyika, ukobvu (T) hwemhete inofa inowanzosarudzwa kubva pa32 ~ 127mm (hudiki hudiki muChina hwave 13mm).

Hurefu hunobudirira hwepellet mill die hole (L) : Hurefu hunoshanda hwe ring die hole zvinoreva kureba kwegomba rekuburitsa zvinhu (kuumba).Iyo yakareba hurefu hunobudirira hwegomba rekufa, iyo yakareba nguva yekuwedzera kwezvinhu mugomba rekufa, iyo yakaoma mapellet anogadzirwa, ipapo kusimba uye kunaka kwepellets zviri nani.Pane zvinopesana, mapellets akasununguka, chiyero chepulverization chakakwira, uye mhando yepellet inoderedzwa.

Tapered inlet dhayamita (D) yegomba rekufa: dhayamita yegomba rekudyisa rinofanira kunge rakakura kudarika dhayamita yegomba rekufa (d), kuitira kuderedza kupokana kwezvinhu mugomba, kuitira kuti vagone kupinda. mugomba rekufa.Kune matatu maitiro ekutanga emakomba ekudyisa, anoti gomba rakatwasuka, gomba rekoni uye gomba rakakomberedzwa.Kune zvigadzirwa zvine yakakwira fiber yemukati, nekuda kwekusiyana kwehunhu hwegranulation, zvinodikanwa kuderedza kupikisa kuburikidza negomba rinofa mukuita granulation.Nechikonzero ichi, gomba rekufa rinofanirwa kugadzirwa kuita zvikamu zviviri, chikamu chekudya chekudyara L uye chikamu chekubvisa decompression R, chinoti L+R=T.Kune matatu maitiro ekutanga e decompression discharge gomba: gomba rakatwasuka, gomba rekoni uye kusanganiswa kwegomba rekoni uye gomba rakatwasuka, pakati paro iro gomba rakatwasuka uye gomba rekoni ndiro rinonyanya kushandiswa, iro repamusoro aperture rakati kurei zvishoma pane die hole diameter d. , kudzika kwayo kunoenderana nekuenderana kunoshanda hurefu hwekushanda L. Mune zvimwe zviitiko, kunyanya kana iyo yekugadzirisa zvinhu ichionekwa mugomba rakadzika rekumanikidza ichawedzera uye plug, zvakakodzera kushandisa shanduko yekubatanidza yekoni gomba uye gomba rakatwasuka , kana kushandiswa. yegomba rekoni.