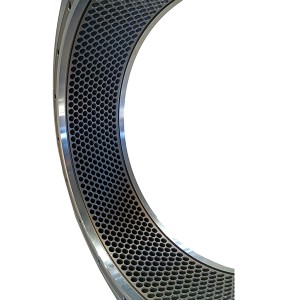

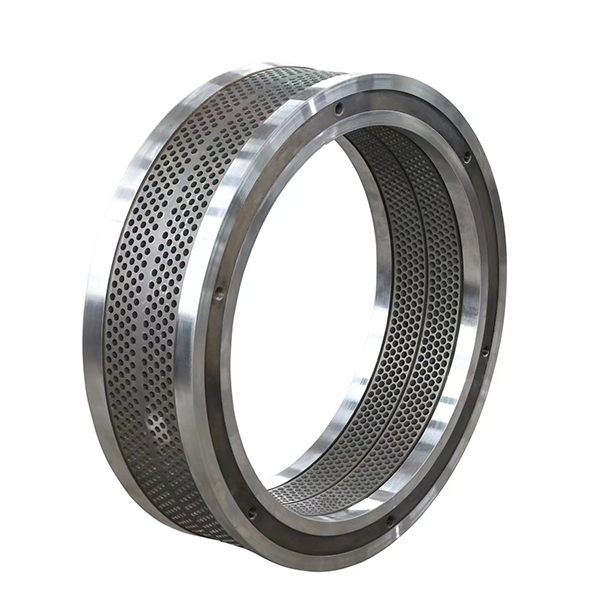

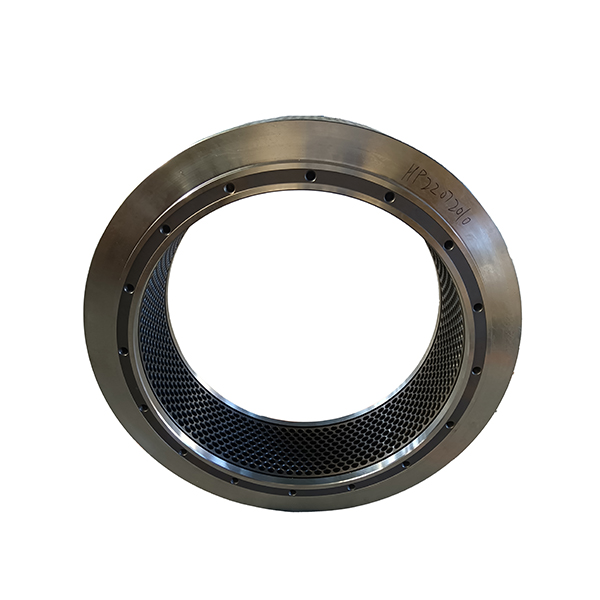

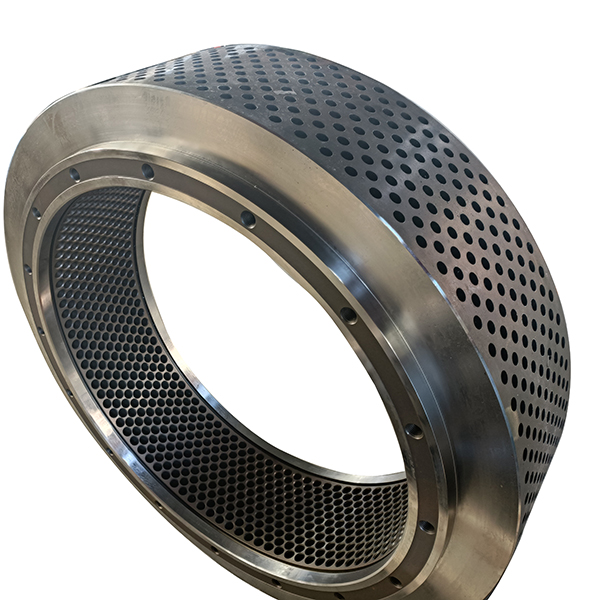

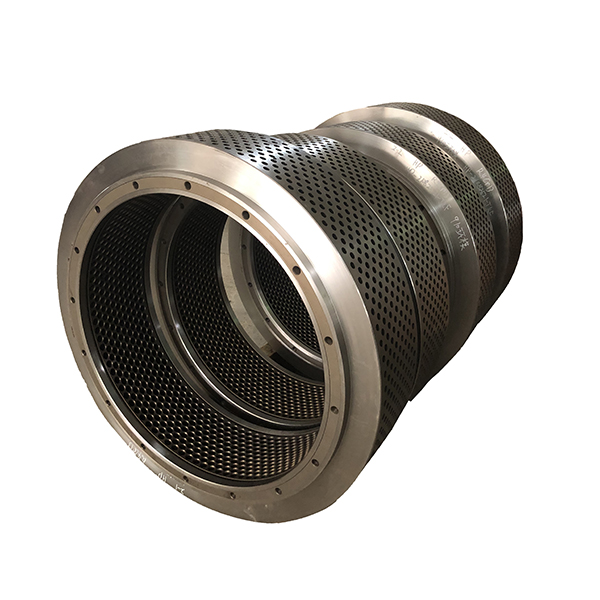

Granulator Cpm Series Pellet Die For Wood Pellet Machine High Speed Biomass Wood Big Hole Size Pellet Mill Die

Granulator Cpm Series Pellet Die For Wood Pellet Machine High Speed Biomass Wood Big Hole Size Pellet Mill Die

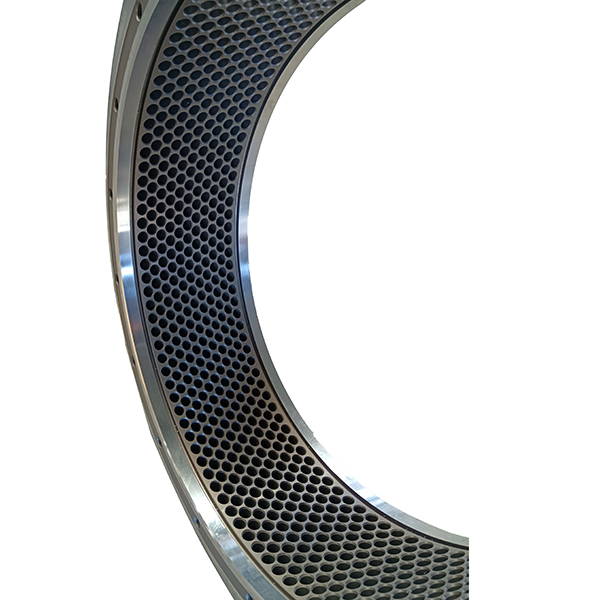

The aperture range of the pellet mill die used for wood pellet material is between 5.0-18.0mm, and the length-aperture ratio, or compression ratio, is between 1:4-1:10.

The compression ratio of the ring die for the wood pellet machine is determined according to the raw material. The compression ratio of different raw materials is different, the harder raw materials ,the smaller compression ratio ; the fluffier raw materials,the bigger compression ratio .That is to say, the fluffier raw materials are more easy to press and form shape.

First of all,under the premise of selecting high quality ring die, should be based on the proportion of production materials, select suitable die hole form, opening hole rate and compression ratio (compression ratio = the effective length of die hole/die hole diameter). On the premise of guarantee the ring die strength, improve the opening hole rate of ring die.For some kinds of material, under the condition of reasonable compression ratio, ring mold wall is too thin, so that the ring die strength is not enough, there will be mold explosion in the production, at this time should be in guarantee ring die hole effective length under the premise , increase the thickness of the ring die and increase the pressure relief hole.

The ring-die compression ratio is the ratio of the effective length of the ring die hole to the minimum diameter of the ring die hole, which is an index reflecting the extrusion strength of the wood pellet machine. The larger the compression ratio, the stronger the extruded wood particles.

Hanpai ring mold focuses on solving the problems of ring mold cracking and low production in the process of wood pellet production. And the use of compound hardening process can increase the service life by more than 50%.

Specification parameters of biomass pellet mill die

Material: high quality stainless steel/alloy steel

Machining aperture: Ø3.0mm-18.0mm

Outer diameter of workpiece: Ø500mm-1100mm

Inner diameter of workpiece: Ø400mm-900mm

Surface hardness: stainless steel HRC 52-56/alloy steel HRC 58-62

Compression ratio: According to customer requirements

pellet mill roller shell 690

vertical ring die wood pellet mill

690 diameter ring die wood pellet machine

vertical ring die wood pellet mill

high quality biomass burners wood pellet die

pellet mill parts roller shell

high quality biomass burners wood pellet die

biomass wood pellets mill die

biomass pellet machine sawdust straw fuel

big hole size pellet mill die

910mm inner diameter mould for biomass pellet production line

18mm biomass pellet making die