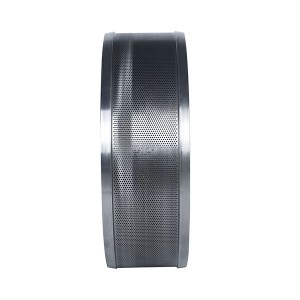

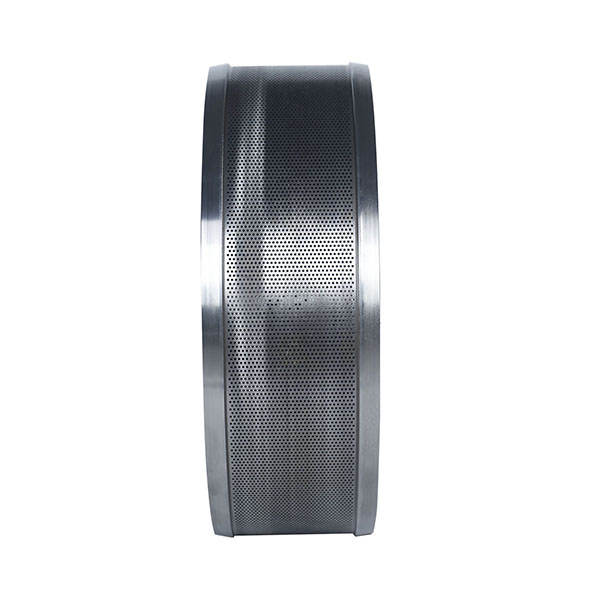

Various Customized Ring Mold Fish Pellet Making Machine Good Surface Finish Apply For Famsun Series Customized Top Quality Pellet Mill Die

Various Customized Ring Mold Fish Pellet Making Machine Good Surface Finish Apply For Famsun Series Customized Top Quality Pellet Mill Die

The aperture of the ring die used in fish feed ranges from 1.5 to 5.0mm, and the length-aperture ratio, or compression ratio, ranges from 1:10 to 1:25. It requires neat particles, low powder content and certain stability in water.

Because of the variety of fish, the formula changes greatly, the requirements for equipments are relatively high. But there are many feed enterprises because of the lack of understanding of equipments, use livestock and poultry feed equipments for fish feed production, it is difficult to achieve the stability of fish feed particles in the water, and the powder rate formed in the feeding process will cause water pollution. Happy Mould will design compression ratio and opening hole rate for fish feed pellet mill die according to feed raw materials and feed production equipment. And we use high quality steel, CNC deep hole drilling machine,vacuum quenching furnace and other unique process, which to achieve the required standard of fish feed pellet. It can also make efficiency of production increase 10-40%, improve the quality of particles, improve the yield, and reduce the production cost.

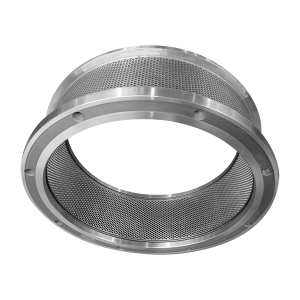

The influence of ring die parameters on feed pellet quality is mainly manifested in the effective length of ring die hole, roughness of die hole,aperture, die hole shape and so on.

1. Effective length of die hole:

The effective length of ring die hole refers to the length of die hole for material extrusion (forming). Generally, the effective length of the straight hole is the thickness of the ring die, and the minimum diameter is the diameter of the die hole itself.

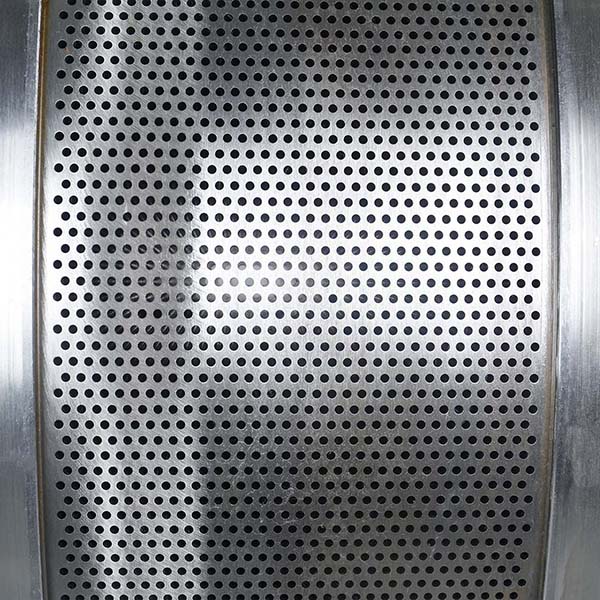

2. Roughness of die hole:

The more smooth the pellet die hole , the easier the material is to be extruded and formed, and the surface of the feed pellets is more better.

3, pellet die hole aperture:

For the ring die of a certain thickness, the larger the aperture, the smaller the ratio of the die hole length to the aperture (length-diameter ratio), and the material is easy to extrude in the die hole.

4. Shape of die hole:

The shape of die hole mainly includes straight hole, step hole, outer cone hole and inner cone hole. The market is dominated by straight holes. The effective length of step holes is less than that of straight holes, so that the resistance of materials in the holes is reduced. The inner cone hole and outer cone hole are mainly used for the material with high fiber content which is difficult to form.

machine for fish feed

floating fish feed pellet machine

fish feed processing machine

fish food pellet machine floating fish feed

machine for fish feed

Buhler 530 fish feed pelleting

Apply For Famsun 420 screw type fish feed pelletizer machine

Buhler 530 ring die floating fish feed machine pellet