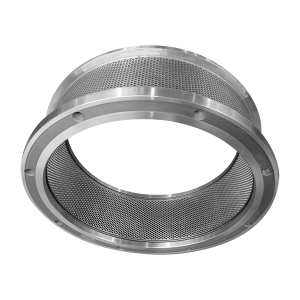

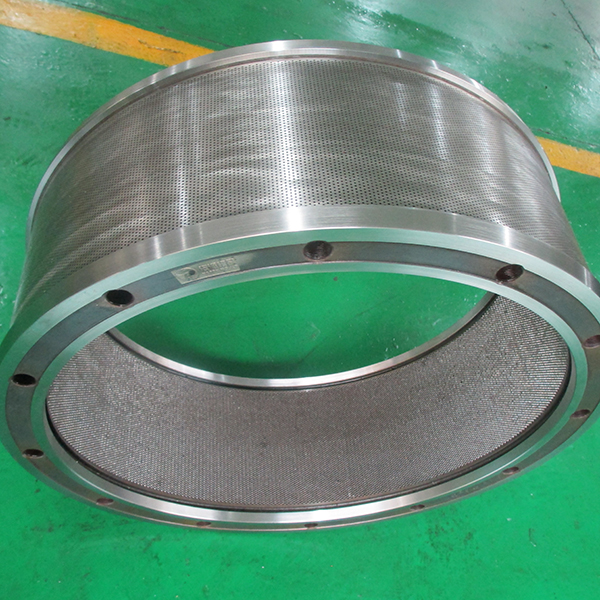

Andritz520 Screw Type Pellet Mill Die/China Dairy Farm Equipment Feed Pellet Machine Accessories Crab Feed Customized

Andritz520 Screw Type Pellet Mill Die/China Dairy Farm Equipment Feed Pellet Machine Accessories Crab Feed Customized

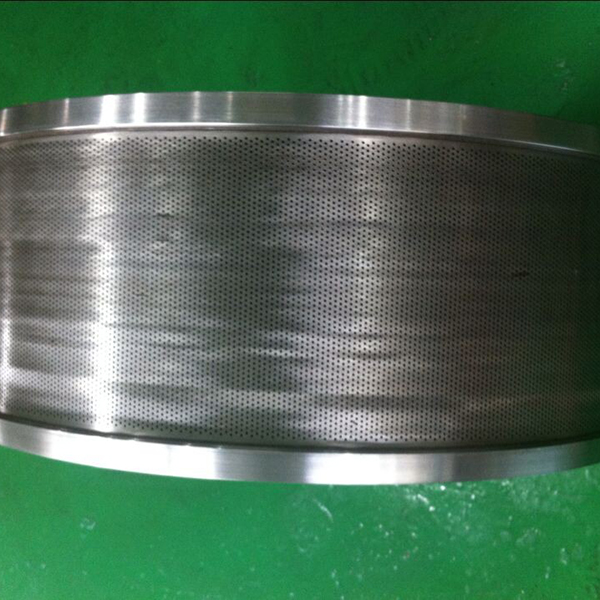

The aperture of the pellet mill die used in making shrimp feed ranges from 0.8 to 2.0mm, and the length-aperture ratio or compression ratio, ranges from 1:20 to 1:35.

Because the hole size is small, compression ratio is relatively high, the overall feed yield is low. Our company has adopted some special production processes, greatly increase the opening hole percentage of the ring die. In addition, we can customize the ring die according to the customer provided formula and production process, which make the output of shrimp material has been greatly improved. For example, aperture 1.0, compression ratio 28-30 ,IDAH 530 ring die can reach 3.5-4t/h; Aperture 0.8, compression ratio 33-35, Famsun 550x170 ring mold (Muyang 600 ring mold) can reach1.5-2t/h. Moreover, the shrimp feed pellets appearance is neat, the powder content rate is low, and the water resistance is good. Reduce production costs by 20-60%, greatly enhance the feed market competitiveness and the profitability for feed enterprises.

Six elements of feed granulation technology

Industry requirements of pellet appearance quality: The industry requirements for the appearance quality of feed pellets in the customer's regional feed market determins everything, which is the starting point for considering all issues (including production process).

Understanding of the effect of raw material quality on pelletizing: The feed formula used by customers and the quality of raw materials selected are objective factors that must be considered.

Conditioning: Whether the conditioning effect of materials can be controlled is the key to ensure the appearance quality of feed particles.

Selection and use of pellet mill die and roller shell: The reasonable selection of ring die compression ratio, press roll tooth shape and the correct use of ring die and press roll are the key to improve feed production efficiency.

Steam control: In the process of pelletizing machine operation steam and feed speed balance control is to ensure the quality of particles, improve the production efficiency of the core.

Equipment condition: Good equipment condition is the guarantee to achieve the above objectives.

vertical ring die pellet mill 1.6mm compression ration 1:26

small hole size crab feed pellet mill die

andritz 520 pellet die for making crab feed

crab feed pellet mill die Andritz520

Screw Type Ring Die For Various Feed Pellet Machine

ring die pellet mill for crab