-

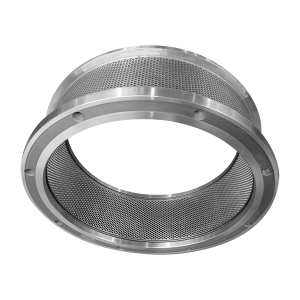

roller shell/agro processing equipment pellet mill spare parts roller shell

The press roll, also called the press roll shell, is one of the main parts of pellet mill, used for processing feed pellets, biofuel pellets, organic fertilizers and other pellets matter.

Our company roller shell is made of high quality material and special heat treatment processing. Its surface is more wearable and hardness is uniform, combined with the Happy Mould ring die, service life will be longer,then making the production safer and smoother.Now there are through groove type, impassable groove type,two ends with holes type and other types.Different sizes and shapes of rollers can be customized according to user demand.

-

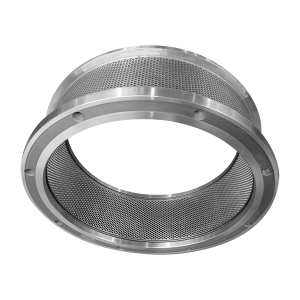

China Supplier Andritz 420 Embrace Hooped Pellet Mill Ring Die for Sale Made in China

As a key equipment in the feed production process, the heart of the pelletizing machine is the ring die (Zhengchang, Muyang, Shende), which is also one of the most easily worn parts in the pelletizing machine. For feed producers, it is urgent to reduce production costs and improve feed pellet quality, which is largely determined by the quality of ring die. Hanpai pig feed pellet mill die using high quality stainless steel material to ensure the long service life of the ring die,

-

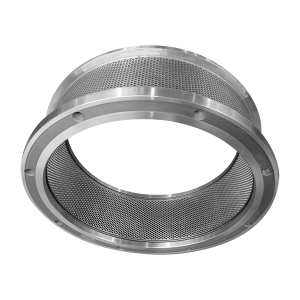

Wood pellet ring mold high quality

The aperture range of the pellet mill die used for wood pellet material is between 5.0-18.0mm, and the length-aperture ratio, or compression ratio, is between 1:4-1:10.

The compression ratio of the ring die for the wood pellet machine is determined according to the raw material. The compression ratio of different raw materials is different, the harder raw materials ,the smaller compression ratio ; the fluffier raw materials,the bigger compression ratio .That is to say, the fluffier raw materials are more easy to press and form shape, the fluffier raw materials contain more fiber, containing more fiber material is easy to form shape. -

Andritz520 Screw Type Pellet Mill Die/China Dairy Farm Equipment Feed Pellet Machine Accessories Crab Feed Customized

Because the hole size is small, compression ratio is relatively high, the overall feed yield is low. Our company has adopted some special production processes, greatly increase the opening hole percentage of the ring die. In addition, we can customize the ring die according to the customer provided formula and production process, which make the output of shrimp material has been greatly improved. For example, aperture 1.0, compression ratio 28-30 ,IDAH 530 ring die can reach 3.5-4t/h

-

Shrimp Feed Pellet Mill Die/Shrimp Feed Production Line Spare Parts Small Hole Size Stainless Steel X46cr13 Material High Compression Ratio Pellet Mill Die

Because the hole size is small, compression ratio is relatively high, the overall feed yield is low. Our company has adopted some special production processes, greatly increase the opening hole percentage of the ring die. In addition, we can customize the ring die according to the customer provided formula and production process, which make the output of shrimp material has been greatly improved. For example, aperture 1.0, compression ratio 28-30 ,IDAH 530 ring die can reach 3.5-4t/h

-

Pellet mill die for pig feed / Professional Manufacturer Directly Supply

Ring die/As a key equipment in the feed production process, the heart of the pelletizing machine is the ring die (Zhengchang, Muyang, Shende), which is also one of the most easily worn parts in the pelletizing machine. For feed producers, it is urgent to reduce production costs and improve feed pellet quality, which is largely determined by the quality of ring die. Hanpai pig feed pellet mill die using high quality stainless steel material to ensure the long service life of the ring die,

-

Andritz Pellet Mill Die/Agricultural Processing Equipment long Working Life Vertical Various Series ring Die Creep Feed Andritz Pellet Mill Die

Creep feed (commonly known as milk substitute, artificial milk), is a kind of feed pellet which replace the whole milk, its main raw material is dairy by-products. The nutritional index of substitute milk material is protein not less than 20%, fat is more than 6%. The particles are relatively fluffy and can be crushed with fingers. There are many factors that affect the quality of granule, among which the formula factor is dominant

-

Buhler420e Pellet Mill Die/ China Factory Agriculture Products Pelletizer Machine Parts Hotselling Ring Die For Animal Feeds Rabbit Feed

Happy Mould use high quality X46Cr13 stainless steel, the stiffness and toughness of this material are very good.After heat treatment, its surface hardness can reaches HRC52-55 and hardness is uniform, which has good wear resistance and corrosion resistance

-

Cpm Series Pellet Die/ Wood Pellet Machine High Speed Biomass Wood Big Hole Size Pellet Mill Die

The compression ratio of the ring die for the wood pellet machine is determined according to the raw material. The compression ratio of different raw materials is different, the harder raw materials ,the smaller compression ratio ; the fluffier raw materials,the bigger compression ratio .

-

Bio Fertilizer Granulator Machine/ High Productivity Machine Die Pellet Mill Die From China

Fertilizer formula is mainly composed of inorganic fertilizer, organic fertilizer, mineral and so on. The inorganic fertilizer in compound fertilizer, such as urea is corrosive to the ring mold,the ring die hole and inner cone hole are weared severely by mineral ,so the material of the ring mold should be selected stainless steel X46Cr13. Compound fertilizer ring die aperture is generally large, range between 3.0-6.0mm, due to the large friction coefficient ,the hole is difficult to discharge

-

Cat Litter Pellet Mill Die / Hanpai Factory Ring Mold High Precision Cat Litter Making Machine Low Compression Ratio Pellet Mill Die

The aperture of the pellet mill die used for cat litter pellet is usually between 1.3 to 3.0mm, because cat litter is cold pelleting ,so compression ratio is low (it’s about 1:3 – 1:5). Hanpai ring die holes are arranged neatly, the hole surface is smooth as a mirror, the discharge is smooth and full, the production efficiency is increased by more than 30% compared with peers. In order to control the uniformity of blank internal material

-

Zhengchang420d Pellet Mill Die/ Machinery Parts ring Mould For Rumination Feed (Cattle and Sheep)

The aperture range of the pellet mill die used for rumination feed (cattle and sheep) is between 3.0-7.0mm, and the length-aperture ratio also called compression ratio is between 1:6-1:12. Because the crude fiber content in the rumination feed formula is high, the compression ratio should not be set too high, otherwise the pelleting will be relatively difficult and the service life of the ring die will also be shorter. Our company can carry out special compound hardening process for ring die according to customer’s requirements, so that the service life of ring die is increased by more than 50% on the original basis.