Zhengchang Pellet Mill Die/Farm Feeding Accessory Good Price High Production Capacity Livestock And Poultry Feed Zhengchang Pellet Mill Die

Zhengchang Pellet Mill Die/Farm Feeding Accessory Good Price High Production Capacity Livestock And Poultry Feed Zhengchang Pellet Mill Die

The aperture of the pellet mill die used for livestock and poultry feed is between 2.5-6.0mm, and the compression ratio is between 1:5-1:15.

The scope of livestock and poultry feed including cover is mainly pig feed, laying chicken feed, broiler feed, meat duck feed, laying duck feed, etc. In the past, these feed raw materials generally use corn, wheat, soybean meal, vegetable meal, cottonseed meal and other conventional raw materials, the quality of feed pellets is not very high, so it is considered relatively easy to process,most enterprises do not pay special attention to the value of the ring mold to these feed production. Now because of food shortage, various feed enterprises are studying raw materials that can replace these general raw materials, such as DDGS, rice, sorghum, sunflower meal, etc. Because of the intensive breeding, the breeding enterprises use material line, packing auger and other equipment to transport feed, then the requirement to feed powder rate is higher than before . Feed production efficiency is significantly reduced, and customer complaints increase, ring mold service life is also greatly reduced, even the total output of a ring mold only 1/3 of the original. Hanpay Mould according to the above situations, according to the formula and the different requirements for particles,production efficiency,service life, customize the ring die production process , to meet customer requirements, developed a unique compound hardening process, to improve feed production efficiency by 10-20%, reduce the powder rate and extend the service life of the ring die by 30-100%. It has been well received by customers.

Formula: cellulose, fat, calcium and phosphorus content

Ring die: degree of finish, aperture ratio, compression ratio

Equipment: equipment selection and process

Operator: skill, responsibility

Environment: temperature, humidity

|

Feed Varieties |

Hole Diameter(mm) |

Compression Ratio |

|

Poultry&livestock feed |

2.5-6.0 |

1:5-1:15 |

|

Shrimp Feed |

0.8-2.0 |

1:20-1:35 |

|

Fish feed |

1.5-5.0 |

1:10-25 |

|

Crab feed |

1.5-5.0 |

1:15-26 |

|

Biomass and Fertilizer |

5.0-18 |

1:4-1:10 |

|

Cattle and sheep feed |

3.0-7.0 |

1:6-1:12 |

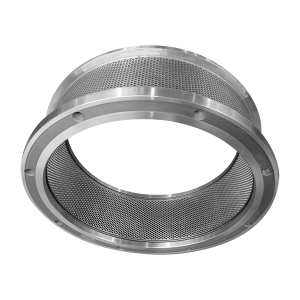

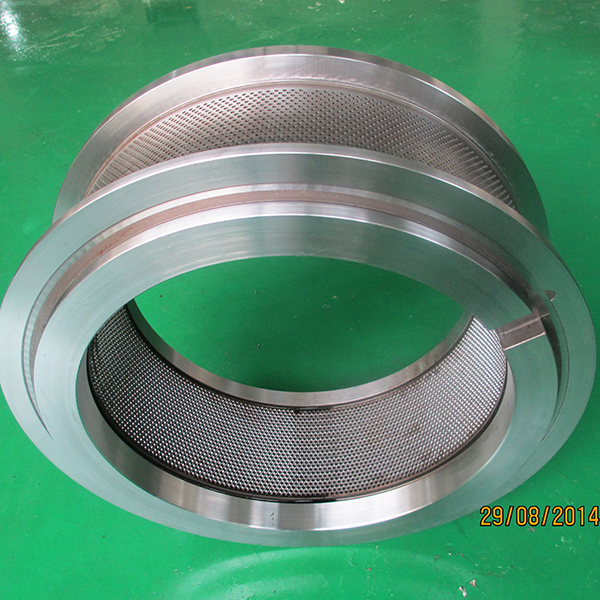

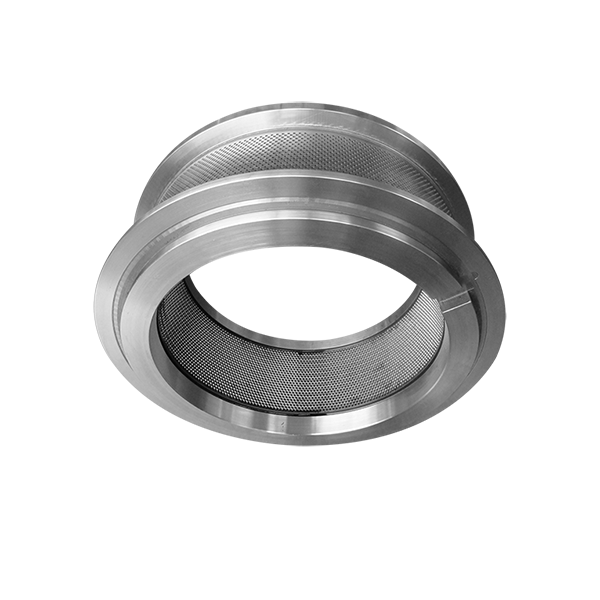

poultry pelleting machine parts ring die

animal food processing machine poultry feed pellet mill die compression ratio 1:13

poultry feed pellet mill die zhengchang 420D

poultry pellet machine