High Efficient Hanpai Factory Ring Mold High Precision Cat Litter Making Machine Low Compression Ratio Pellet Mill Die

High Efficient Hanpai Factory Ring Mold High Precision Cat Litter Making Machine Low Compression Ratio Pellet Mill Die

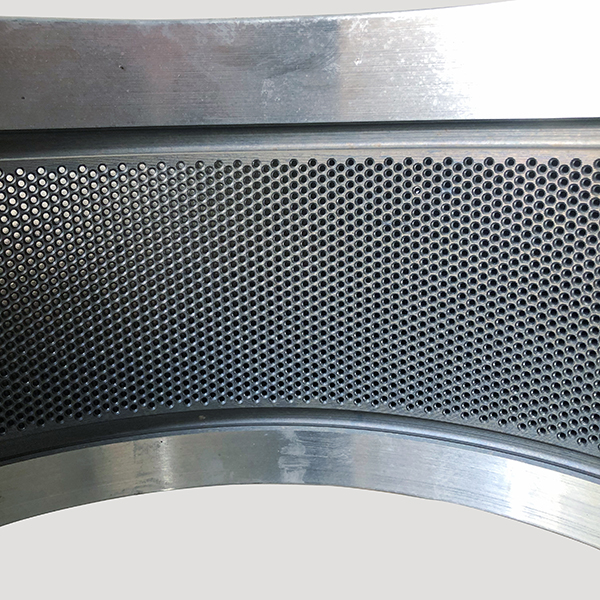

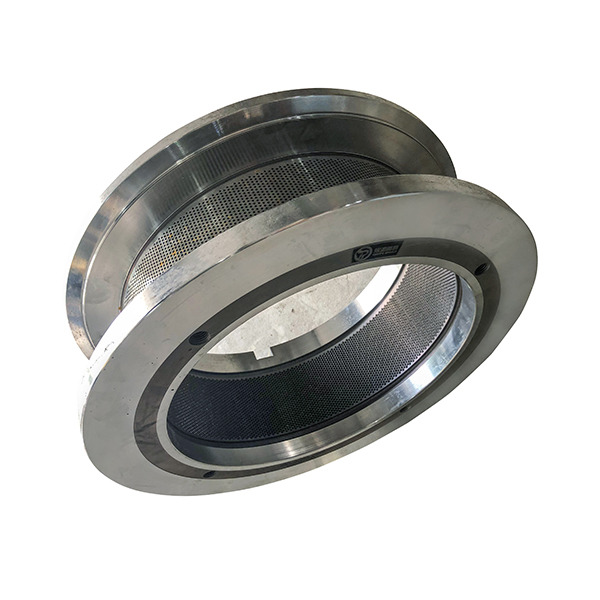

As a key equipment in the feed production process, the heart of the pelletizing machine is the ring die (Zhengchang, Muyang, Shende), which is also one of the most easily worn parts in the pelletizing machine. For feed producers, it is urgent to reduce production costs and improve feed pellet quality, which is largely determined by the quality of ring die. Hanpai pig feed pellet mill die using high quality stainless steel material to ensure the long service life of the ring die, the use of CNC deep hole drilling on the die hole processing to ensure the die hole smooth, avoid forming the crooked hole, so as to achieve the ring die fast discharge, good pellet quality and other characteristics; After vacuum heat treatment, the high wear resistance and high strength of the ring die material are guaranteed, and the smoothness of the die hole is effectively protected.

Because the fodder is not conducive to eating, the Happy Mould decompresses the feed through making two or more step release holes to reduce the amount of feed compression in order to avoid the feed is too squeezed. The suitable compression ratio can reduce the hardness then texture can be loose , which is convenient for suckling pigs to eat.

Maintenance of pellet mill die

1. When the ring die is not used for a period of time, the original feed should be extruded with non-corrosive oil, otherwise, the heat of the ring die will dry and harden the original feed left in the die hole, resulting in the following situation:

(1) When the operation starts, the die hole is blocked and the material cannot be squeezed out;

(2) At the beginning of production, the strength of the ring die is weakened due to high stress, which may lead to the cracking of the ring die;

(3) Some die holes are blocked, the output is reduced, and the benefit is reduced.

2. After using the ring die for a period of time, check whether there is a local protruding part in the table of the ring die. If there is such a phenomenon, apply the polishing machine to grind off the protruding part, so as to ensure the yield of the ring die and the service life of the press roll.

3. If the die hole is blocked and the material is not discharged, it can be re-pelleted after oil immersion or oil boiling. If the pelleting still cannot be done, the clogged material can be drilled out with an electric drill, then the oily material and fine sand are used after grinding and polishing.

4. When loading or unloading the ring die, do not use hard steel tools such as a hammer to punch the surface of the ring die.

5. Use records of the ring die should be made for each shift so as to calculate the actual service life of the ring die.

6. The ring die is stored in a dry and clean place. If it is stored in a wet place, it will cause corrosion of the die hole and reduce the service life of the ring die or prevent the discharge of the die.

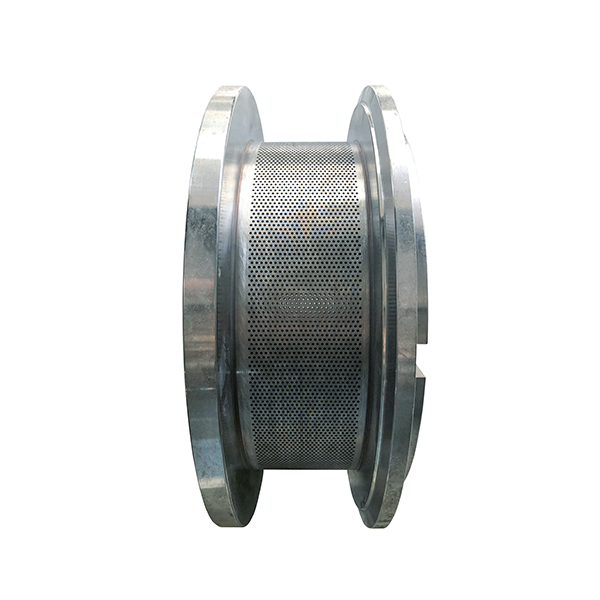

High Quality ZhengChang Pellet Mill Dies for Making Pet Product Cat Litter

cat litter pellets

ring die for making cat litter pellets

wood sawdust pellet machine for cat litter